Réalisations

Measurement of clockwork taps with QMTProjector-100

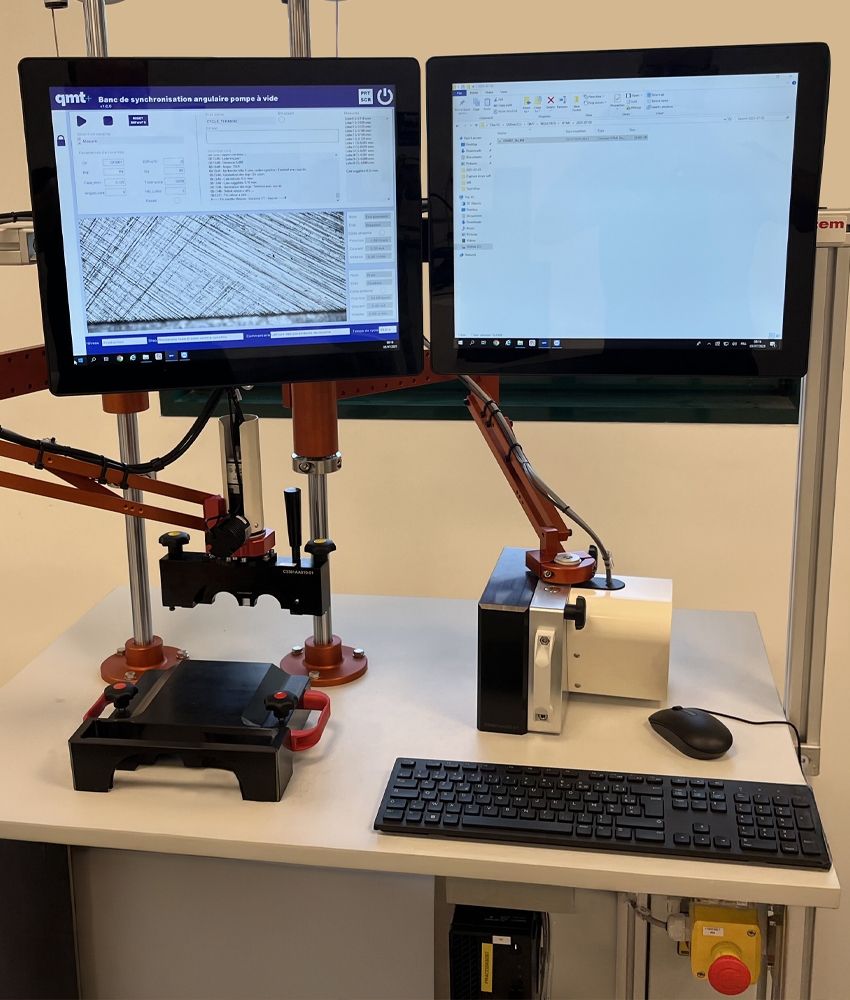

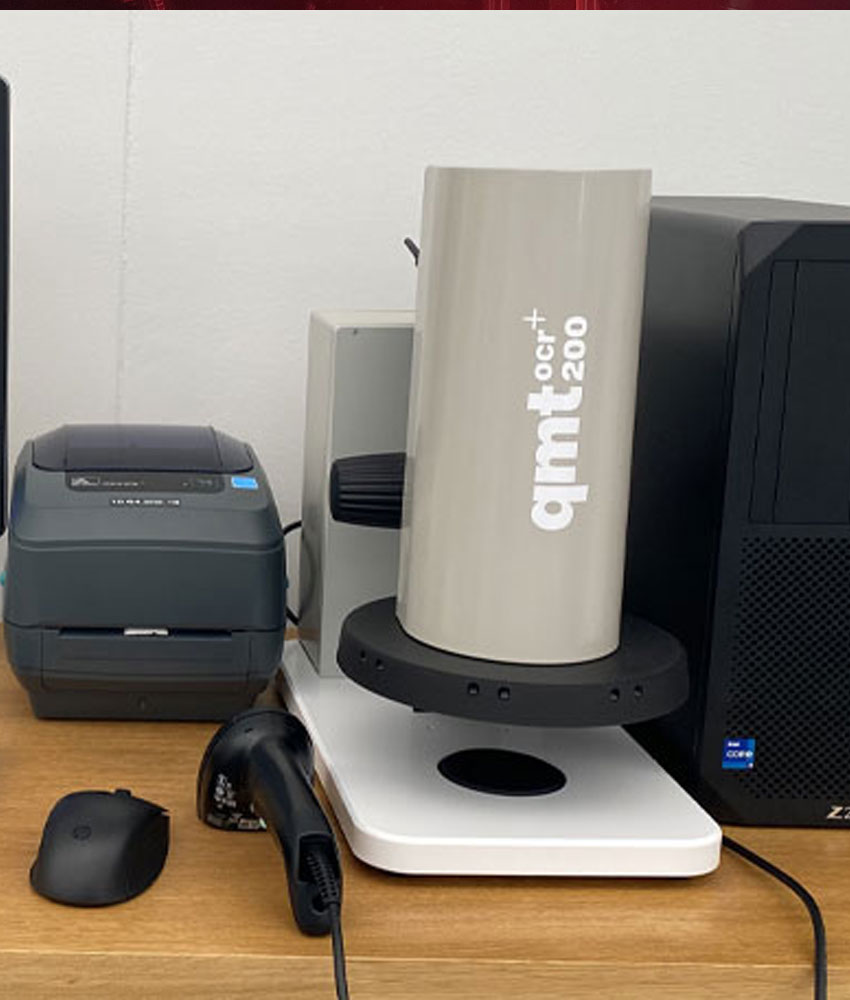

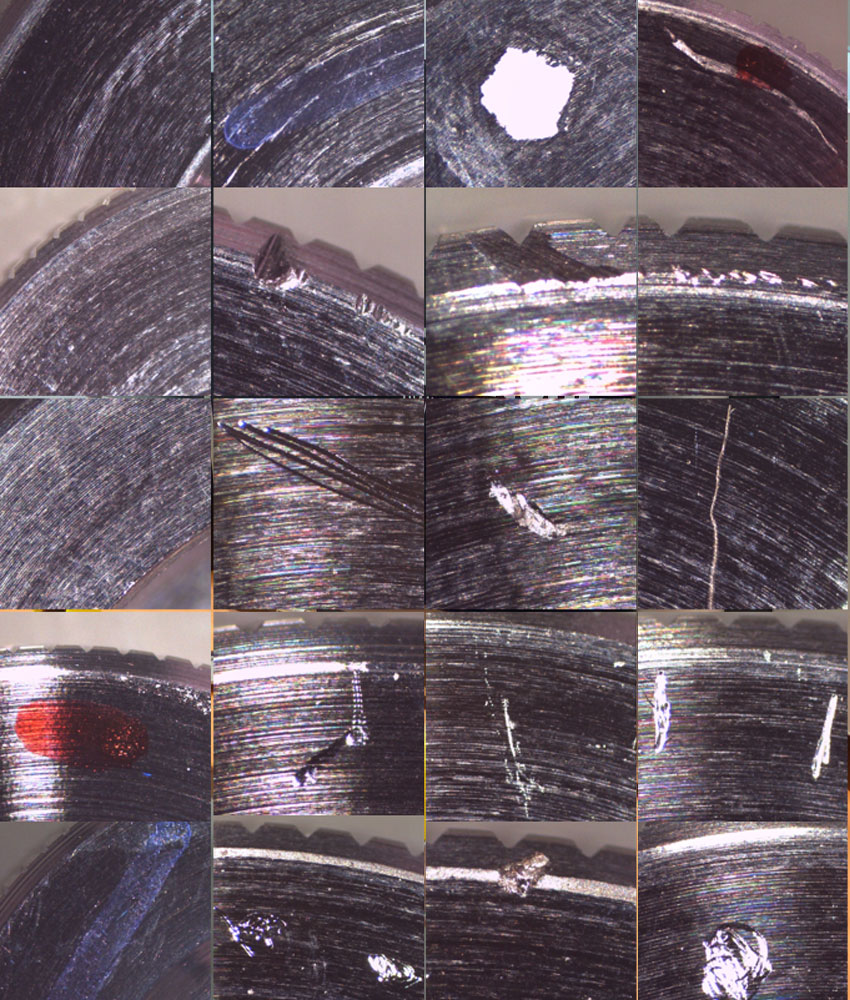

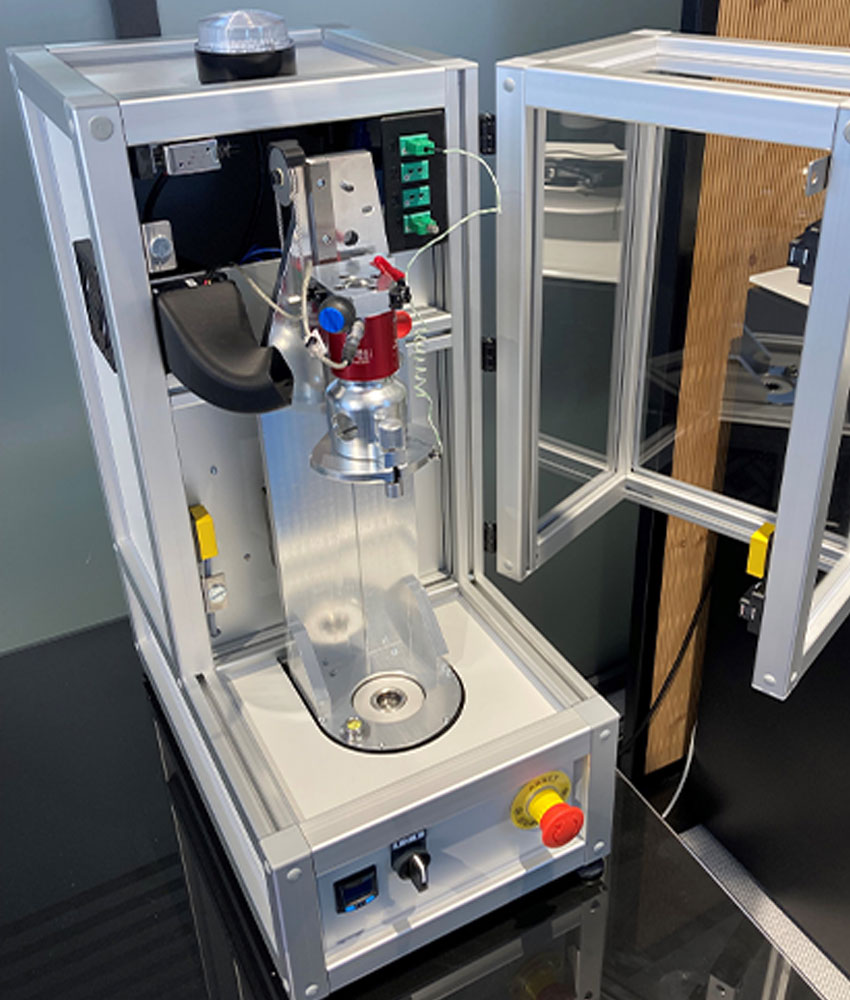

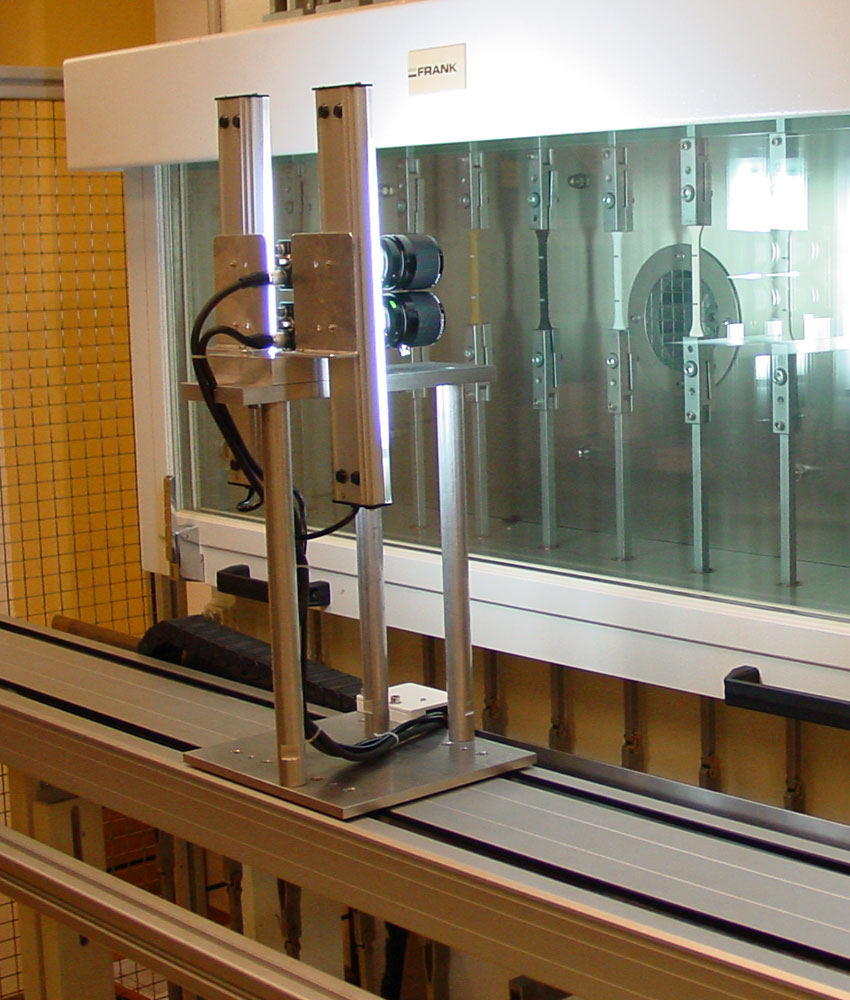

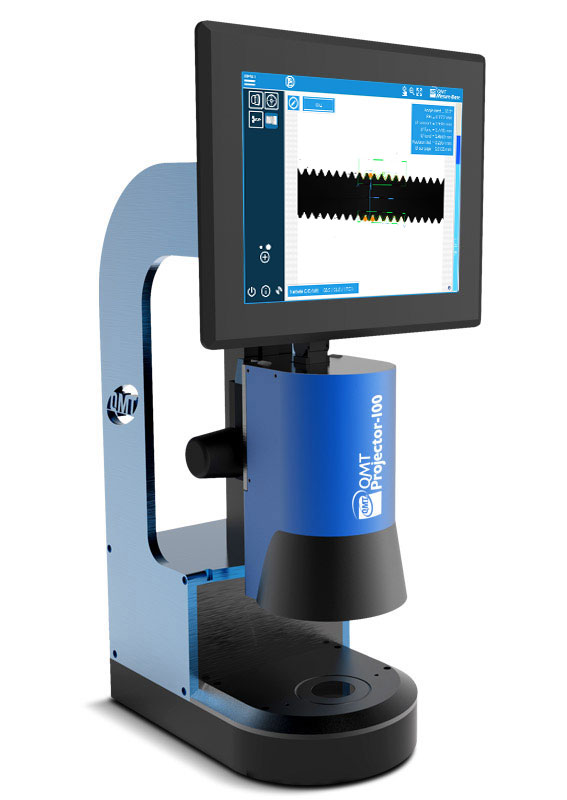

The quality of the micro threads is a requirement of the watchmaking sector, a tool check before the operation is the only guarantee of an optimal result. The QMTProjector-100, a high precision measuring device, is perfectly suited for the control of watch taps. This control device benefits from the QMTMesure-Base software for high-precision dimensional measurement (without any programming).

Very high precision instantaneous measurement

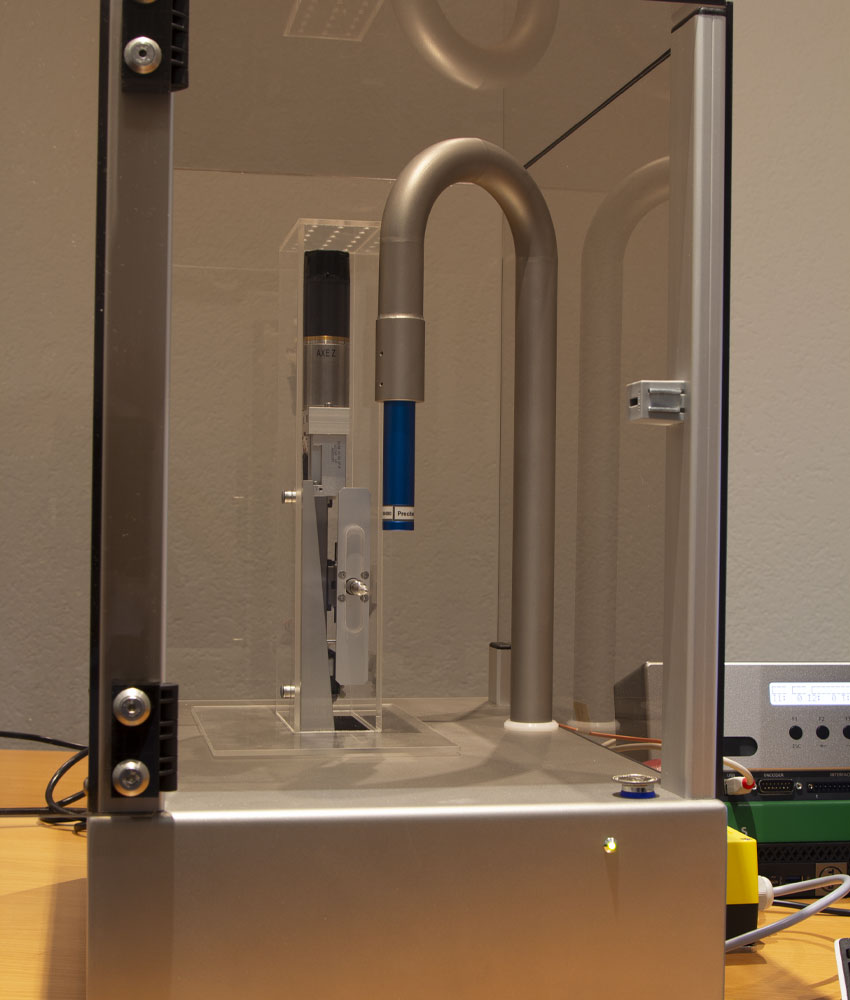

The QMTProjector-100 is a measuring device accessible to all and intended particularly for production control in the microtechnology sector. Robust design and equipped with an integrated computer, this control device benefits from the QMTMesure software range.

- Reduced dimensions

- Ease of use, no programming

- Measurement accuracy

- Personalization of the equipment with the “Fit For You” program

- Improved measurement capability with QMTJust

Measure the main dimensional characteristics of taps with diameters 0.3 to 1.4mm (S03 - S1.4).

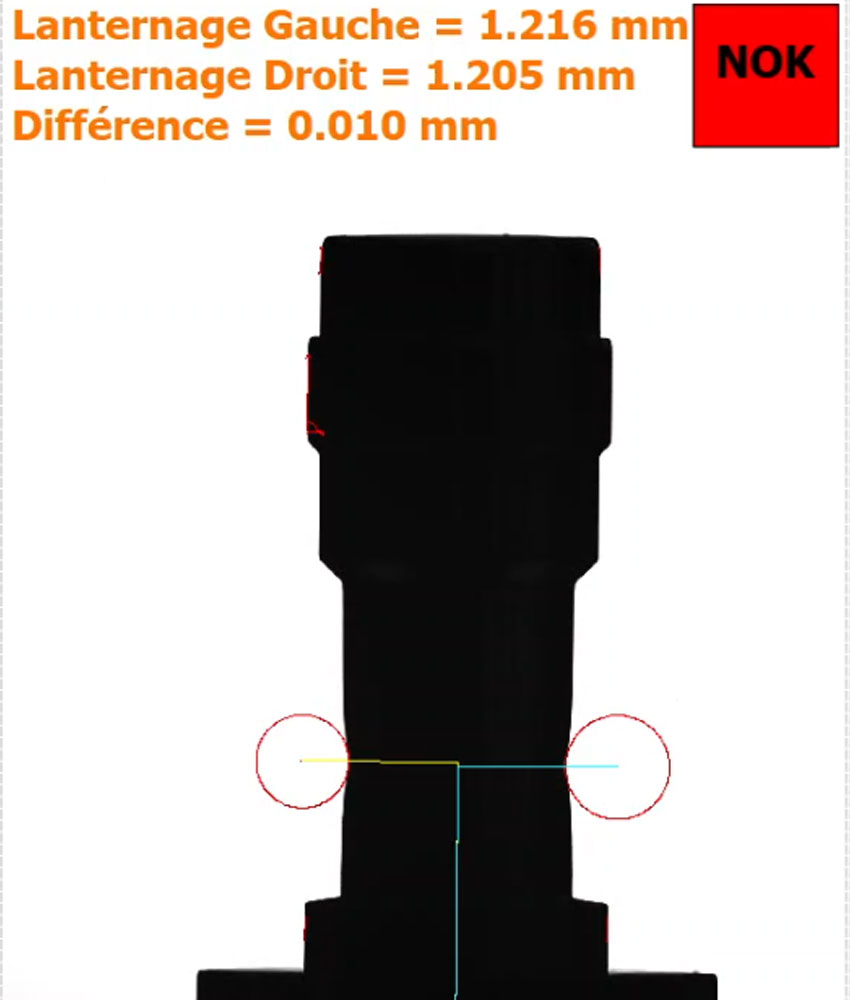

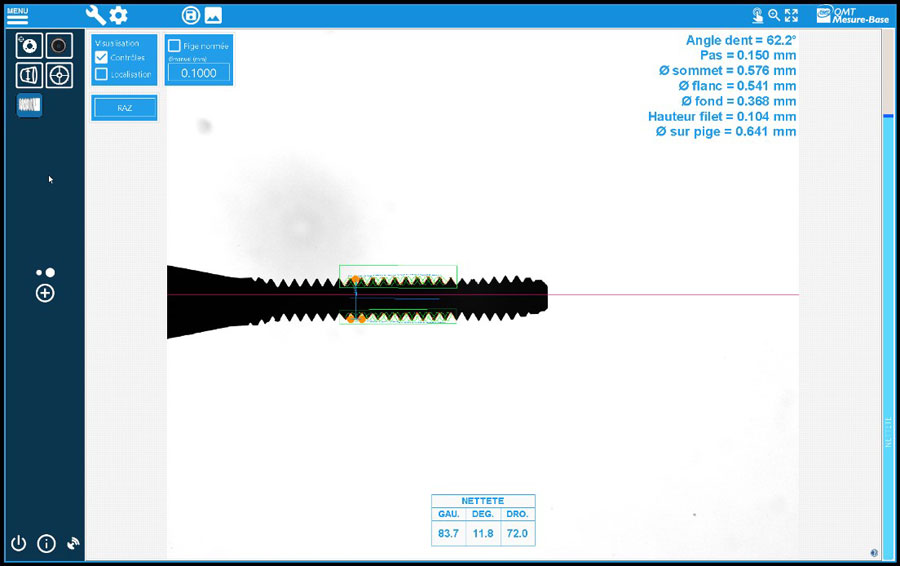

The measures to be carried out:

- The tooth angle with a tolerance of 1 °

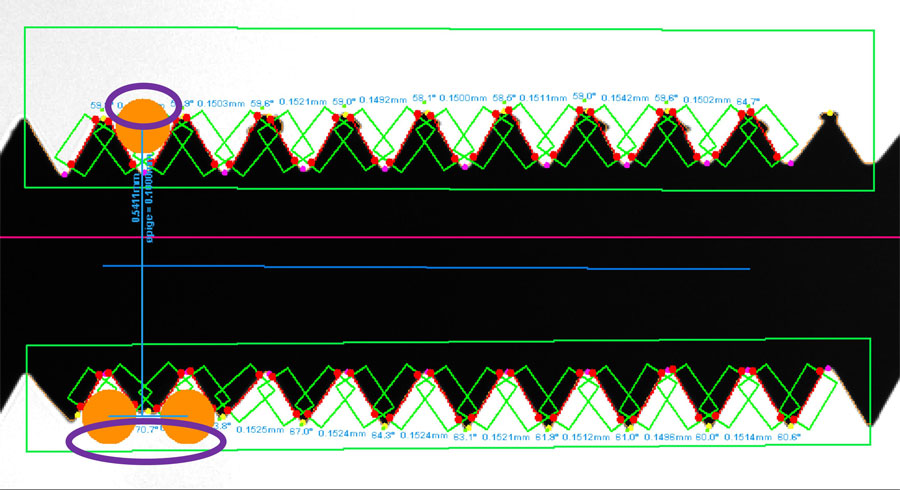

- The pitch with a tolerance of 10µm

- The top, flank and bottom diameters with a tolerance of 8µm

- Net height

- Diameters on rods with a tolerance of 10µm

A specific measurement function has been developed to allow all measurements to be carried out without any programming.

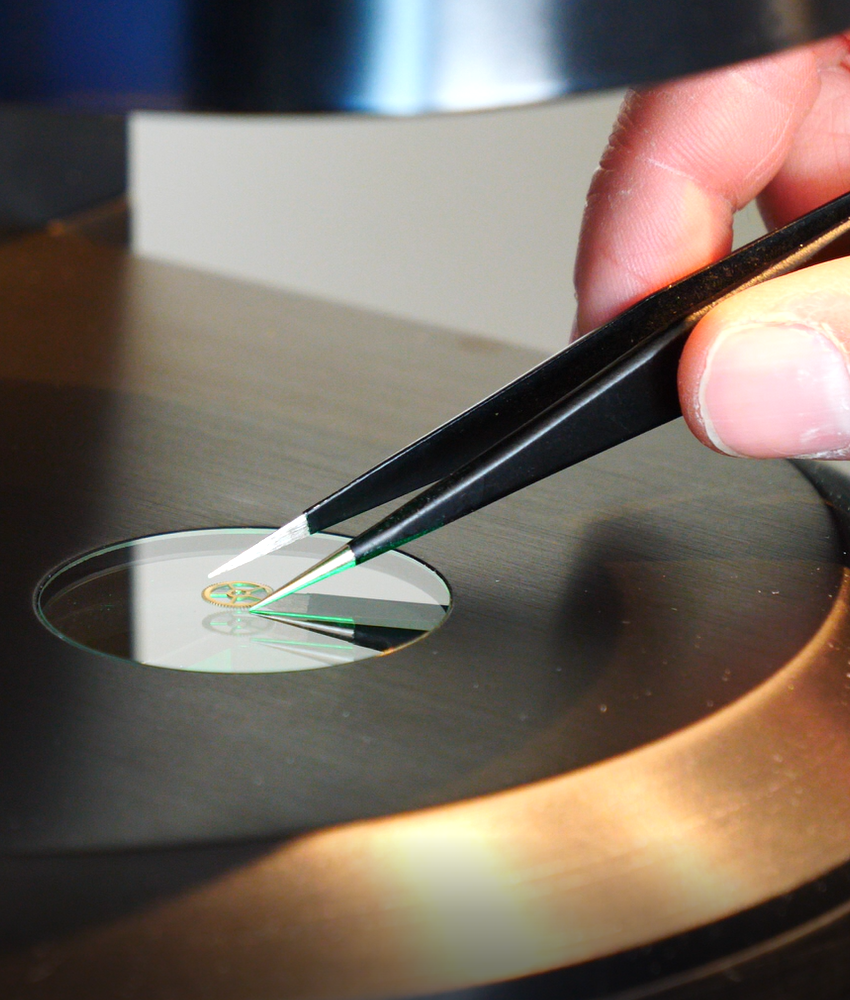

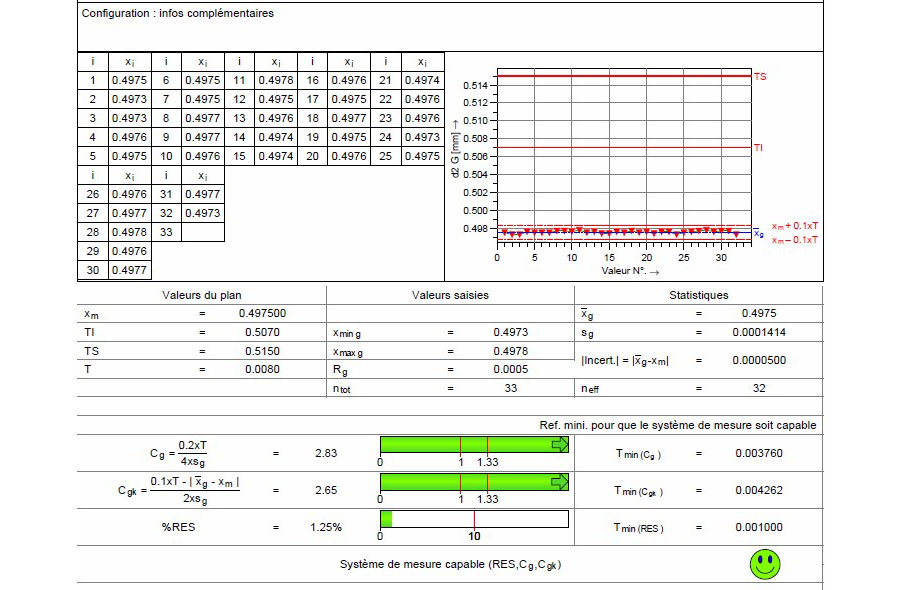

After removal of the tap on a specific fixture, the measurements are automatically carried out, they are precise to the micron and repeatable as specified in the NIHS standard.

In order to achieve the capability objectives, the QMTJust function has been implemented. With the performance of the equipment and the software, the capability objectives were reached and verified by an MSA study

To meet the demand, Qualimatest offered, as part of its F4U program, a specific version of the QMTProjector-100 with a field of view reduced to 4.2 x3.5mm.

In order to be able to verify the adequacy of the QMTProjector-100 with the needs of the customer, a first phase of rental of the equipment was implemented. It was thus possible to validate the performance before initiating the second phase of purchase of the QMTProjector-100.

The equipment is integrated in the production workshop. It is available for manufacturing personnel who, thanks to the ease of use, can take measurements to set up machines and monitor the quality of the manufactured parts.

The QMTProjector-100 has met all metrological requirements. Its ease of use made it possible to go into production very quickly with a limited need for staff training.

An advanced measurement function without programming

The measurement methods integrated into the function

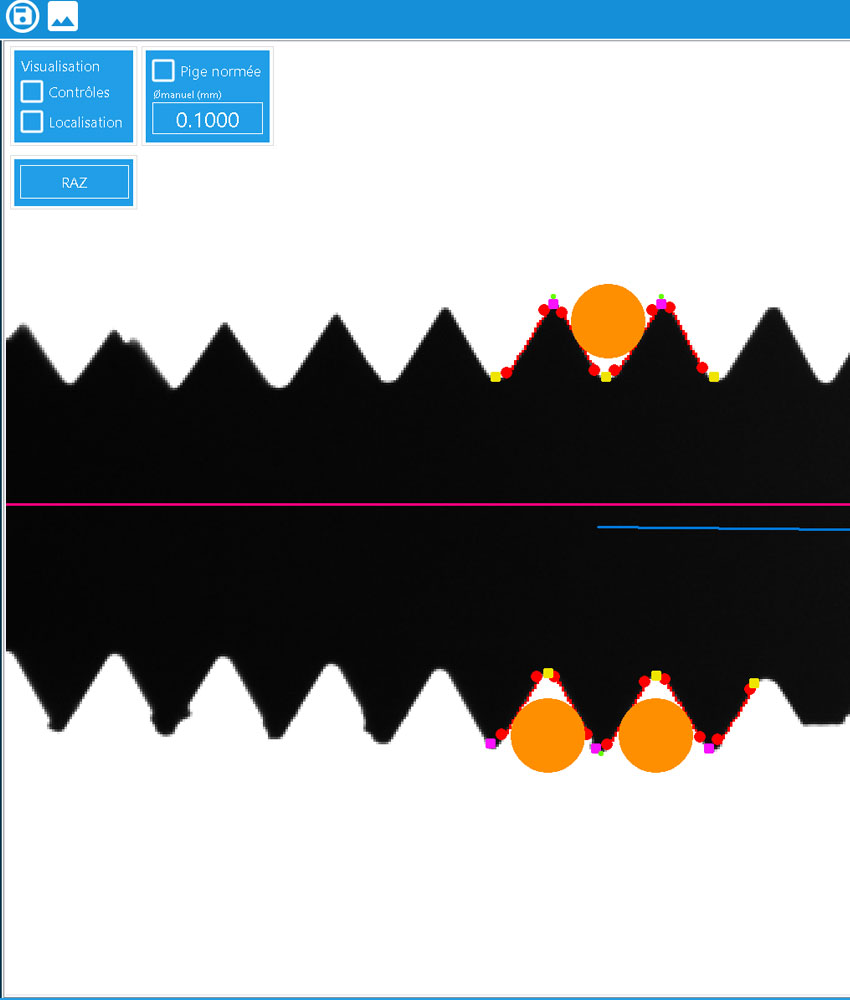

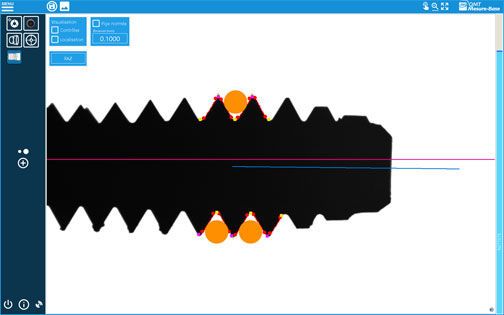

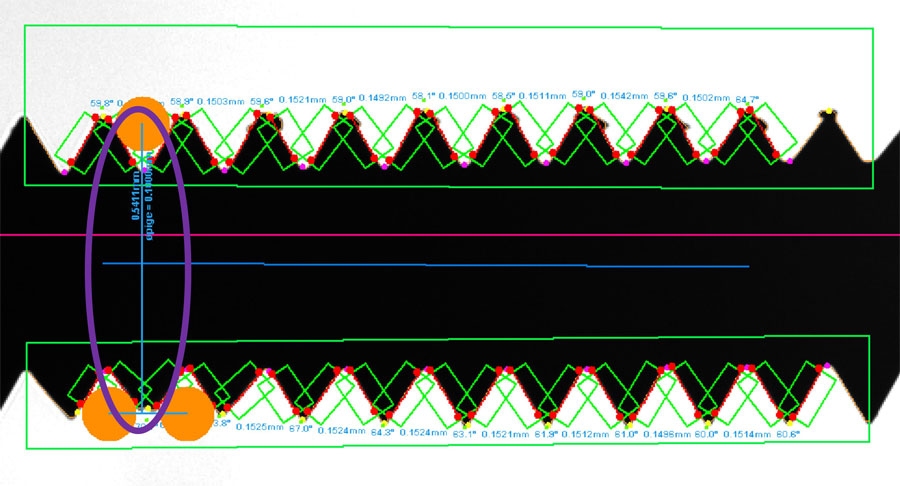

The tap is positioned in profile view in the field of view

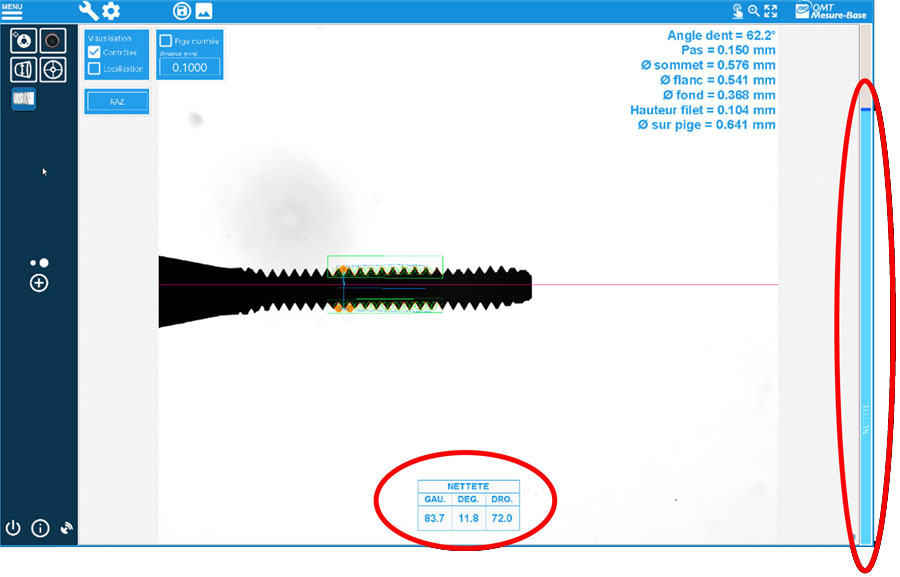

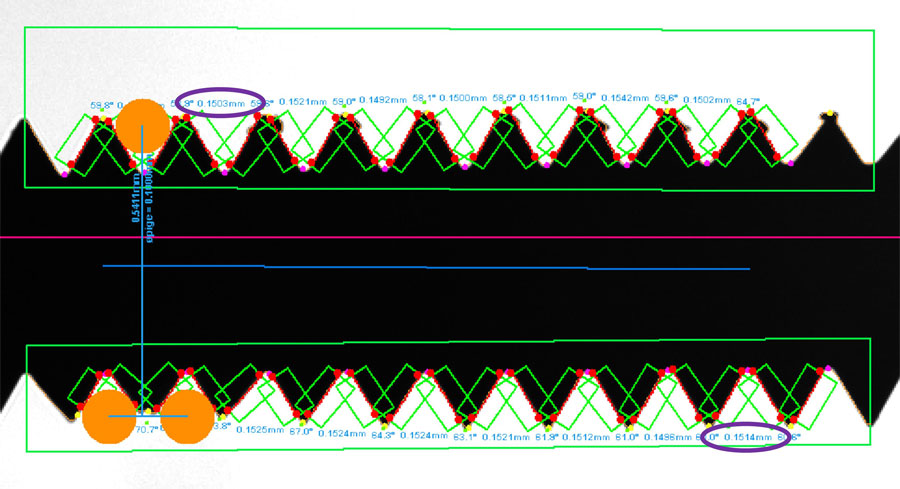

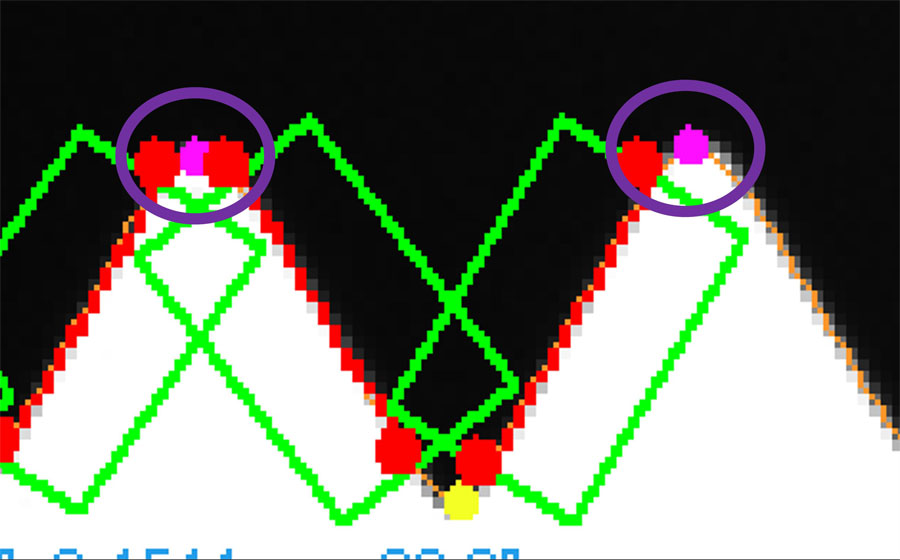

Positioning with trim adjustment allows adjustment of sharpness and perpendicularity using the following indicators

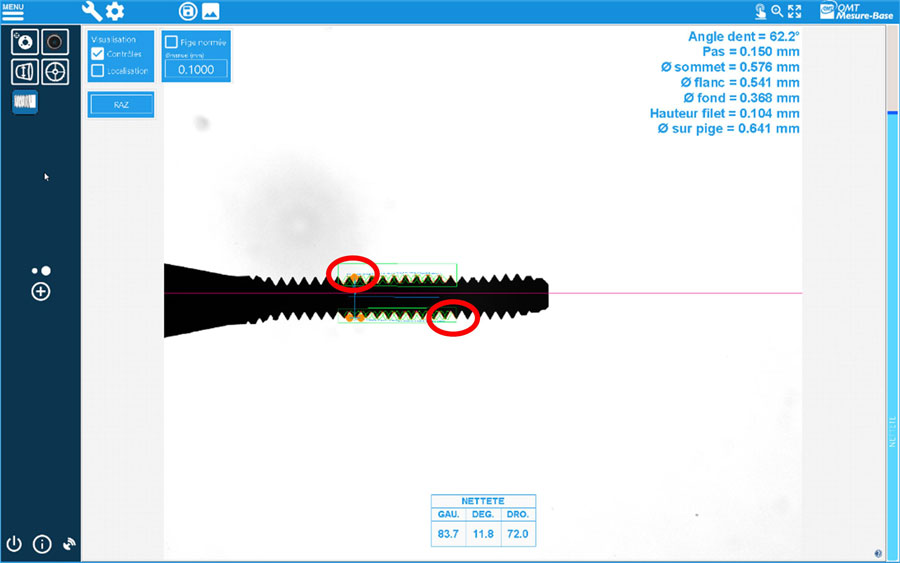

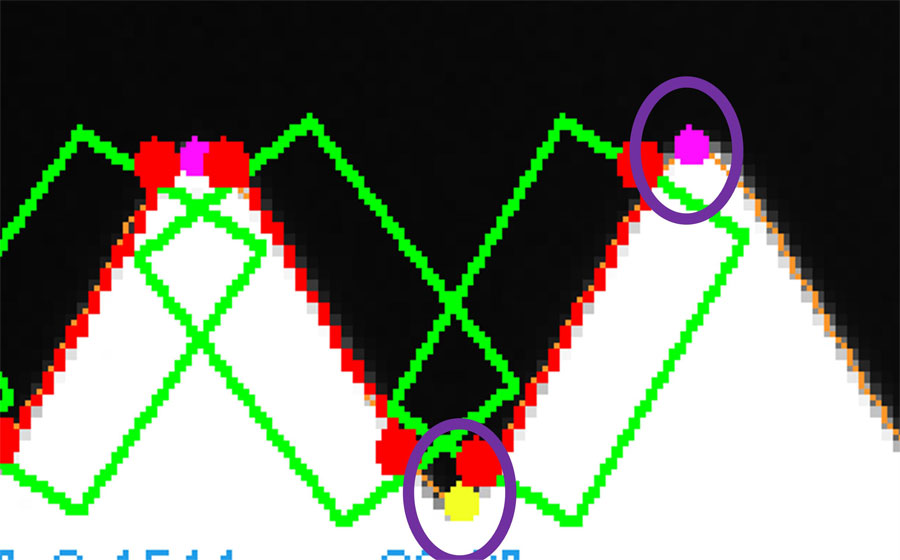

The operator has the free choice of the zone to be checked by 2 clicks on the screen corresponding to the start and the end of the zone (top left and bottom right):

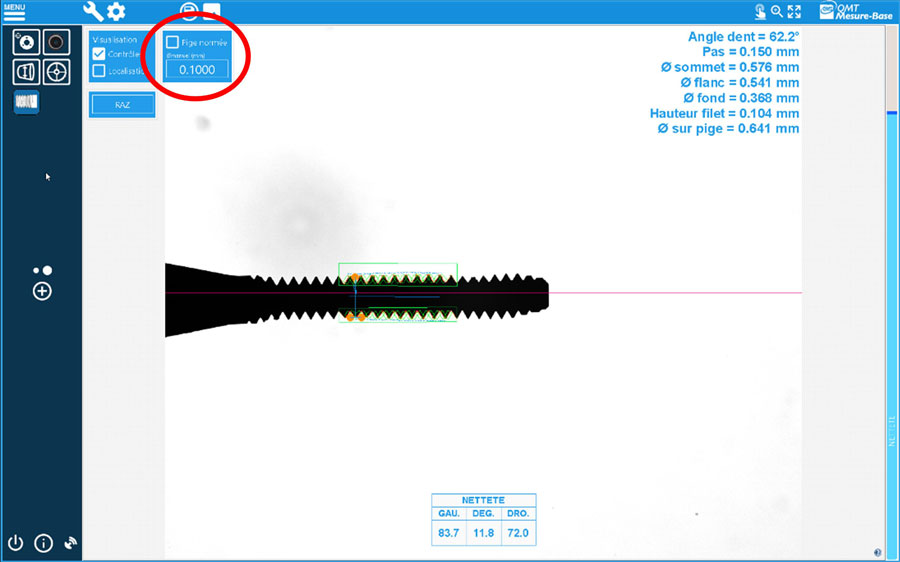

In the zone concerned, the profile search and the determination of the type of tap are automatic (S0.3, S0.4,… ..) For each type of tap, a standardized gauge is automatically assigned, the operator can choose to use it or impose a different rod diameter:

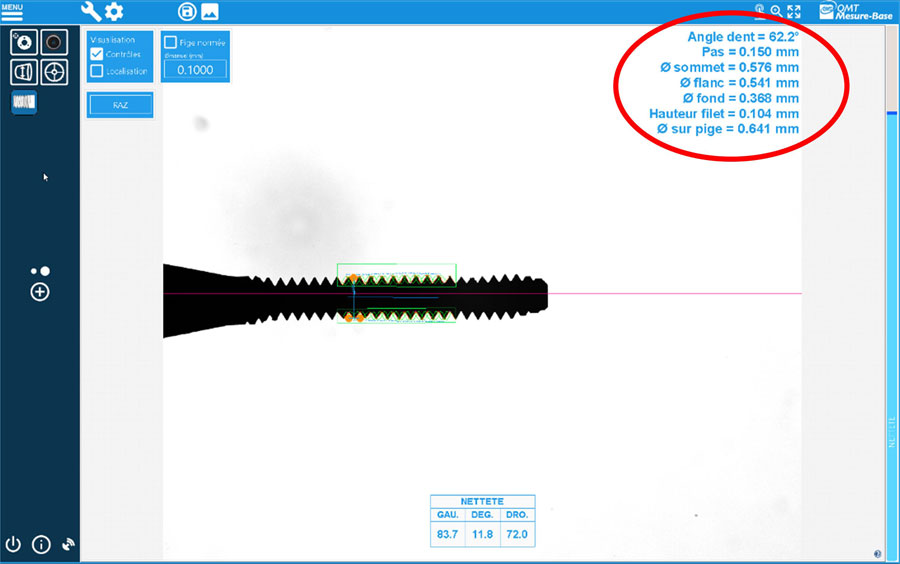

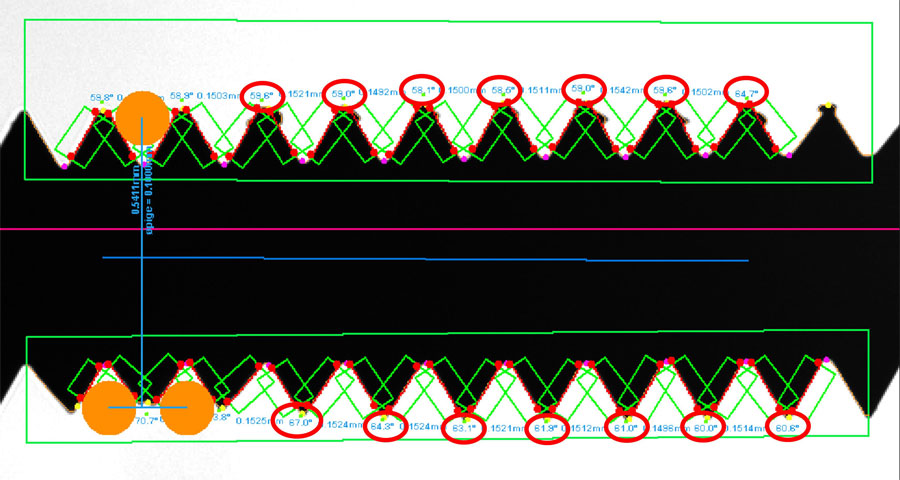

The tap function performs the following measurements:

The tooth angle is the average of all the angles obtained in the measurement area:

The step is the average of all the steps (from top to top) obtained in the measurement zone:

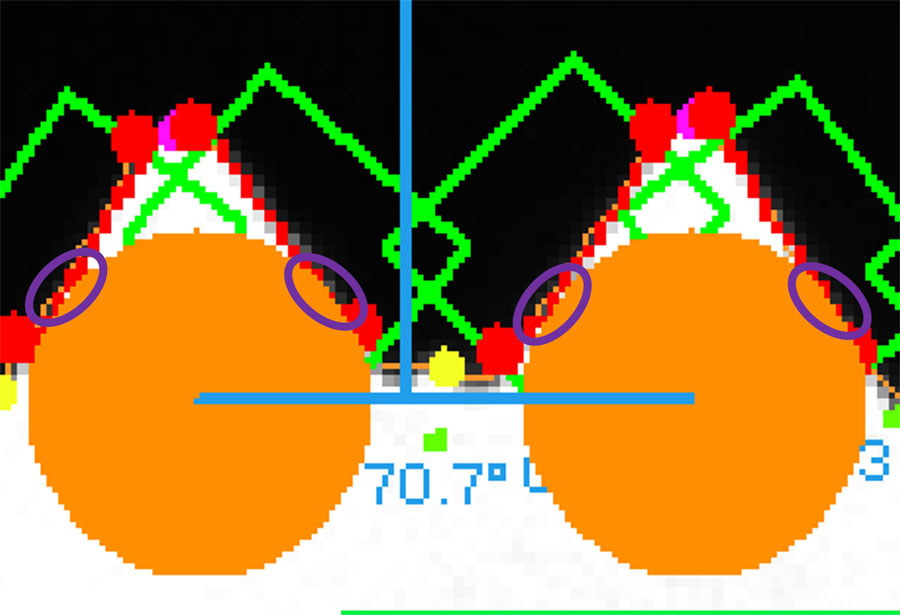

The “top” diameter comes from finding the real top from the intersection of the 2 flanks of each tooth. This diameter is the average of all diameters measured in the area:

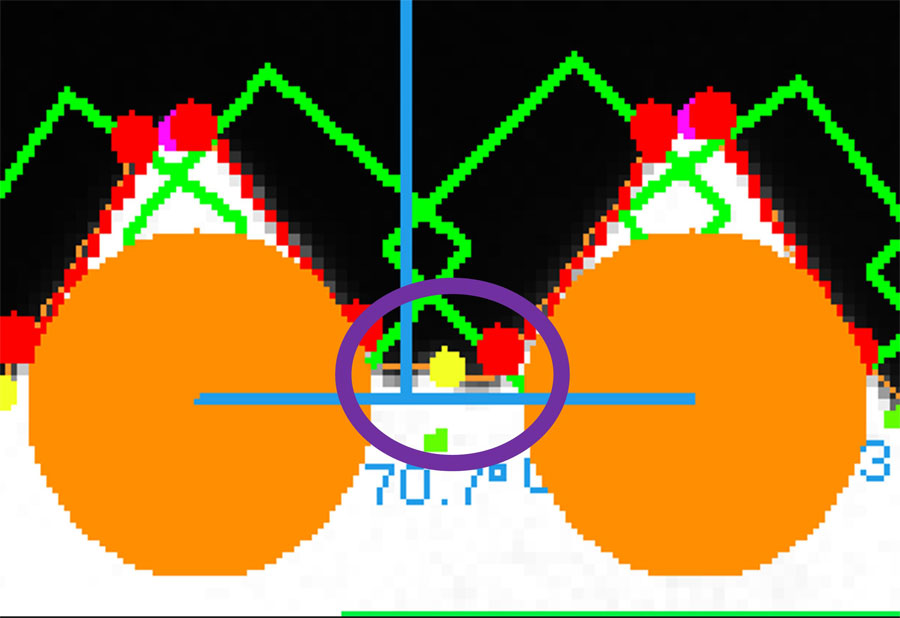

The "flank" diameter is the diameter resulting from the centers of the virtual rods positioned on the tap:

The “bottom” diameter is obtained from the search for the real bottom from the intersection of the 2 flanks of each tooth. This diameter is the average of all diameters measured in the area:

The net height is the average of the heights obtained between each bottom and each top of the net:

The "diameter on rod" is the diameter resulting from the vertices of the virtual rods positioned on the tap:

The diameter "D2" (not mentioned in this list) is the diameter resulting from the meeting point between the pin and the side:

Due to the error induced in the profile view which does not correspond to the mechanical reality (because of the inclination of the teeth), a correlation table was created and implemented for all the diameter measurements from the virtual rods

Guarantee the accuracy of measurement

Qualimatest has developed and implemented the QMTJust algorithm and thus improve measurement accuracy by 16x to achieve << 1µm errors.

More information